Our Products

Metal Splicing Solutions

Advantages

- Joins like and different metal materials

- Substantially reduces power consumption, reducing production costs

- Solid Phase Binging (?) allows for low temp joints, minimizing damage from heat on the components

- Joined metals maintain high electrical conductivity

- No external, consumable materials required to make the joint

- Required air cooling also keeps the joint area clean

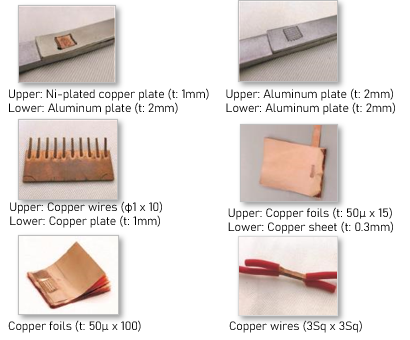

Splicing Samples

Compact Ultrasonic Splicing System

Major Features

•Efficient Splicing by Unique Tool Horn Supporting Mechanism

Unique Tool Horn Support mechanism enables more efficient splicing

The configuration of the press to the horn reduces deformation of the horn, reducing the loss of power during the spicing process by roughly 30%.

•Deep Work Space

The press system is designed to provide as much clearance as possible into the machine footprint

•Full Digital System Control

The system control is completely digital, providing finely tuned parameter settings with the use of our J-Tool management software

•Wide Variety of Oscillation Control

The system can be set to weld by Time, Energy, and/or Depth

•After-Oscillation

In order to cleanly remove the horn from the workpiece, a second oscillation can be programmed once the splicing is completed.

•Self-Diagnosis

The system monitor the weld conditions and outputs and will alarm via buzzer to alert the operator to any abnormal conditions

•Auto Frequency Search by Digital PLL

•Digital Control over Constant Amplitude

•Frequency Search Function

High Power Ultrasonic Splicing System

Major Features

•Efficient Splicing by Unique Tool Horn Supporting Mechanism

Unique Tool Horn Support mechanism enables more efficient splicing

The configuration of the press to the horn reduces deformation of the horn, reducing the loss of power during the spicing process by roughly 30%.

•Deep Work Space

The press system is designed to provide as much clearance as possible into the machine footprint

•Full Digital System Control

The system control is completely digital, providing finely tuned parameter settings with the use of our J-Tool management software

•Wide Variety of Oscillation Control

The system can be set to weld by Time, Energy, and/or Depth

•After-Oscillation

In order to cleanly remove the horn from the workpiece, a second oscillation can be programmed once the splicing is completed.

•Self-Diagnosis

The system monitor the weld conditions and outputs and will alarm via buzzer to alert the operator to any abnormal conditions

•Auto Frequency Search by Digital PLL

•Digital Control over Constant Amplitude

•Frequency Search Function

Ultrasonic Wire Splicing System

Major Features

•Possible to Splice Up to 10sq Wires

•Dimension Control by Depth

•In-line/Parallel Splicing Possible

•Compact Press Unit

Small footprint of Compact press unit saves space.

•Ease of Use

Simple operation does not require expertise of operator

FAQs